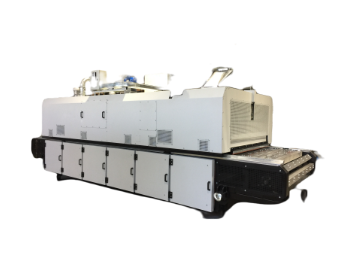

Rameuse

Rameuse, tunnel ovens, attics for various sectors with forced air and high temperature uniformity.

Complete with conveyor belts, units with gripper chains for material dragging.

Modular, with fields at different temperatures, and heated with electric steam/thermal oil heat exchange batteries , or directly on flame with burners.

Suitable for any use, e.g. Drying, stabilizing, heat setting and finishing.

Galvanized, painted or stainless steel construction for any industry.

Each oven is designed with optimized air flows to achieve the best temperature distribution, highest energy savings and shortest heating time.

- Precision - temperature homogeneity with dynamic control system for the best thermal balance even with particularly complex charges

- Innovative laminate-layer type ventilation system to homogenize flows and speed up thermal process time

- Air exchange system with regulating valve.

- Heating elements made of HT steel designed for maximum thermal efficiency and best circulating air flow

- Innovative thermal insulation system with double layer of ceramic-based bonded materials to give the oven the merit of the lowest energy consumption values

- High-flow oven base and insulated with ceramic materials

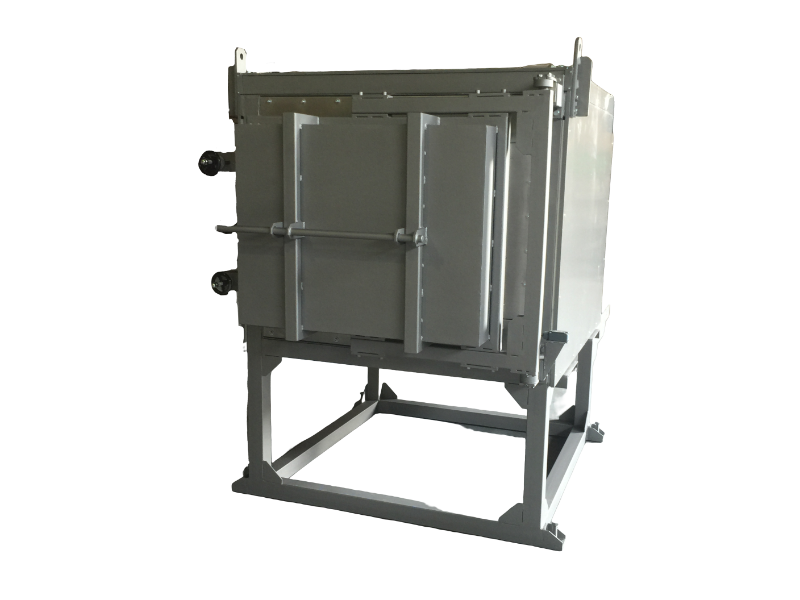

Range of ovens for treatments on metals, typically treatments on brass, steel, etc., with which various types of treatments such as stress relief, tempering, and stabilization can be carried out, with the aim of reducing internal and residual stresses that result from hot and cold working, hardening treatments, and machining, with temperatures ranging from about 150°C to 500°C depending on the materials. These ovens are used, for example, for stress relief treatments of brass components, with temperatures of 250-450°C, and for stress relief treatments after soldering.

Tempering is a heat treatment usually performed after hardening, with the aim of obtaining the desired hardness/tenacity ratio. These ovens are suitable for treatments for temperature ranges from 150°C to 450°C.

A widely used technique for assembly or disassembly operations of mechanical components and transmission organs, which involves using heat-generated thermal expansion to overcome the dimensional interference of two components and create an extremely strong mechanical coupling.