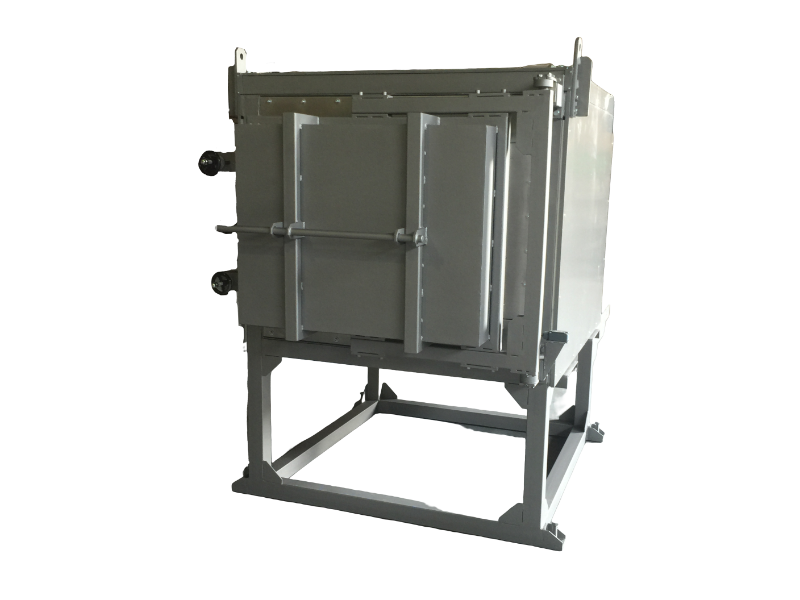

Automotive sheet metal treatment ovens

The oven is built to heat a sheet metal to about 520 – 570°C in a few minutes, this time will vary depending on the temperature at which you want to work the heating plates, which can reach maximum temperatures of about 700 °C

The oven consists of a fixed lower body and a movable upper body, both equipped with a stainless steel heating plate, where a sheet metal to be heated will be deposited, while the upper body can be raised to allow automated loading and unloading of the sheets

Each heating plate will be partitioned into three heating zones lengthwise, ON-OFF and corresponding top and bottom, so a total of 6 zones.

The purpose of this partialization is to be able to use even smaller sizes of aluminum sheet metal and thus not to heat unused zones of the plates, for energy savings.

Main application: automotive body shop sector

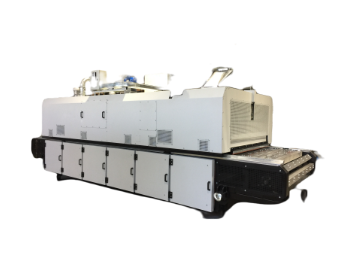

- Precision - temperature homogeneity with dynamic control system for the best thermal balance even with particularly complex charges

- Innovative laminate-layer type ventilation system to homogenize flows and speed up thermal process time

- Air exchange system with regulating valve.

- Heating elements made of HT steel designed for maximum thermal efficiency and best circulating air flow

- Innovative thermal insulation system with double layer of ceramic-based bonded materials to give the oven the merit of the lowest energy consumption values

- High-flow oven base and insulated with ceramic materials

Range of ovens for treatments on metals, typically treatments on brass, steel, etc., with which various types of treatments such as stress relief, tempering, and stabilization can be carried out, with the aim of reducing internal and residual stresses that result from hot and cold working, hardening treatments, and machining, with temperatures ranging from about 150°C to 500°C depending on the materials. These ovens are used, for example, for stress relief treatments of brass components, with temperatures of 250-450°C, and for stress relief treatments after soldering.

Tempering is a heat treatment usually performed after hardening, with the aim of obtaining the desired hardness/tenacity ratio. These ovens are suitable for treatments for temperature ranges from 150°C to 450°C.

A widely used technique for assembly or disassembly operations of mechanical components and transmission organs, which involves using heat-generated thermal expansion to overcome the dimensional interference of two components and create an extremely strong mechanical coupling.